Types of warehouses in Logistics

Warehousing types in logistics are an important and integral part of the supply chain, almost related to all stages from the receipt of raw materials, production in the system to completion. into products and delivered to customers. Types of warehouses in logistics need to be designed and operated according to a system with specific requirements suitable for each specific item. So what types of warehouses are included in the logistics supply chain, what are the characteristics of each type of warehouse, let's learn about this with MIP in the article below.

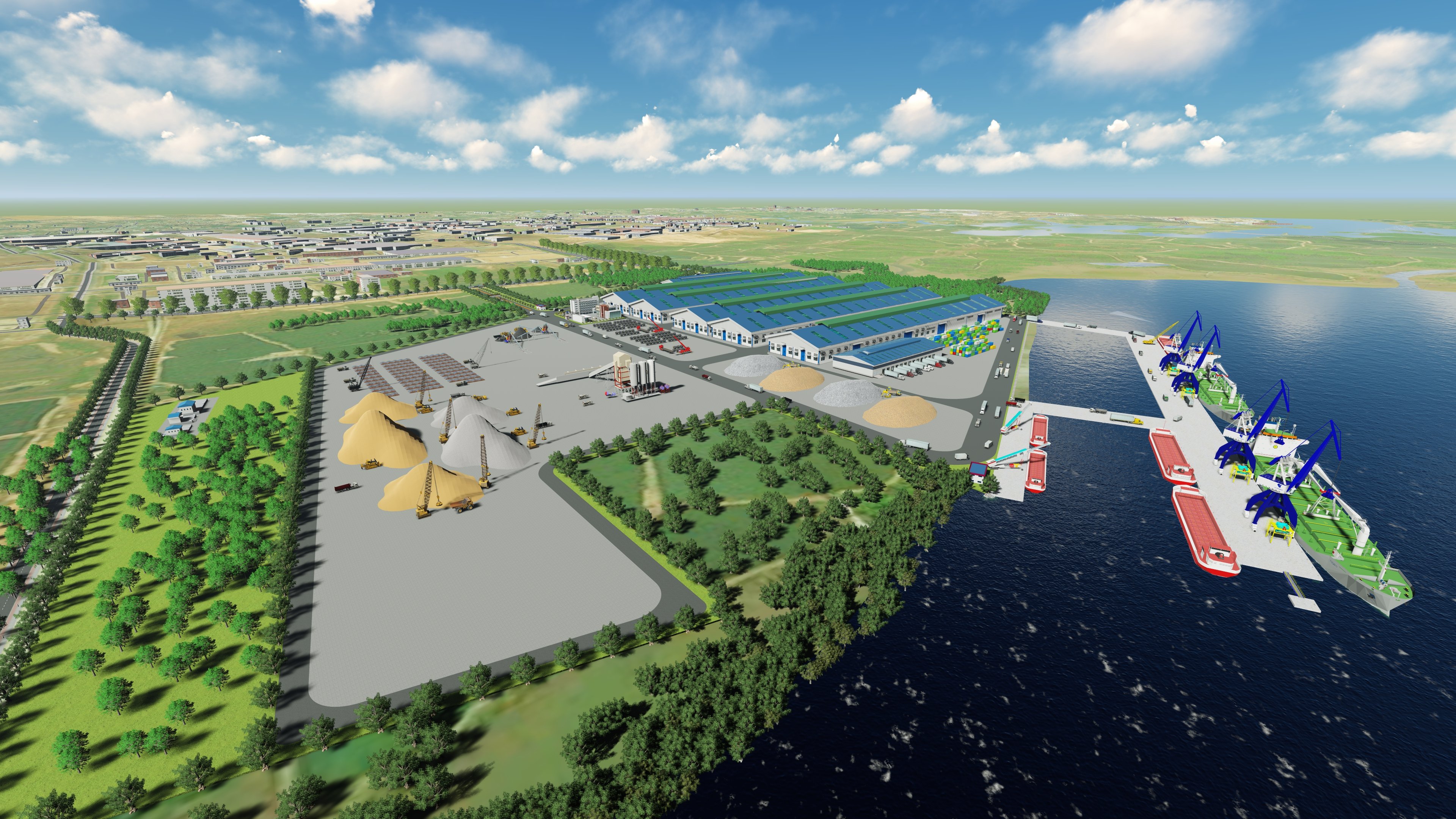

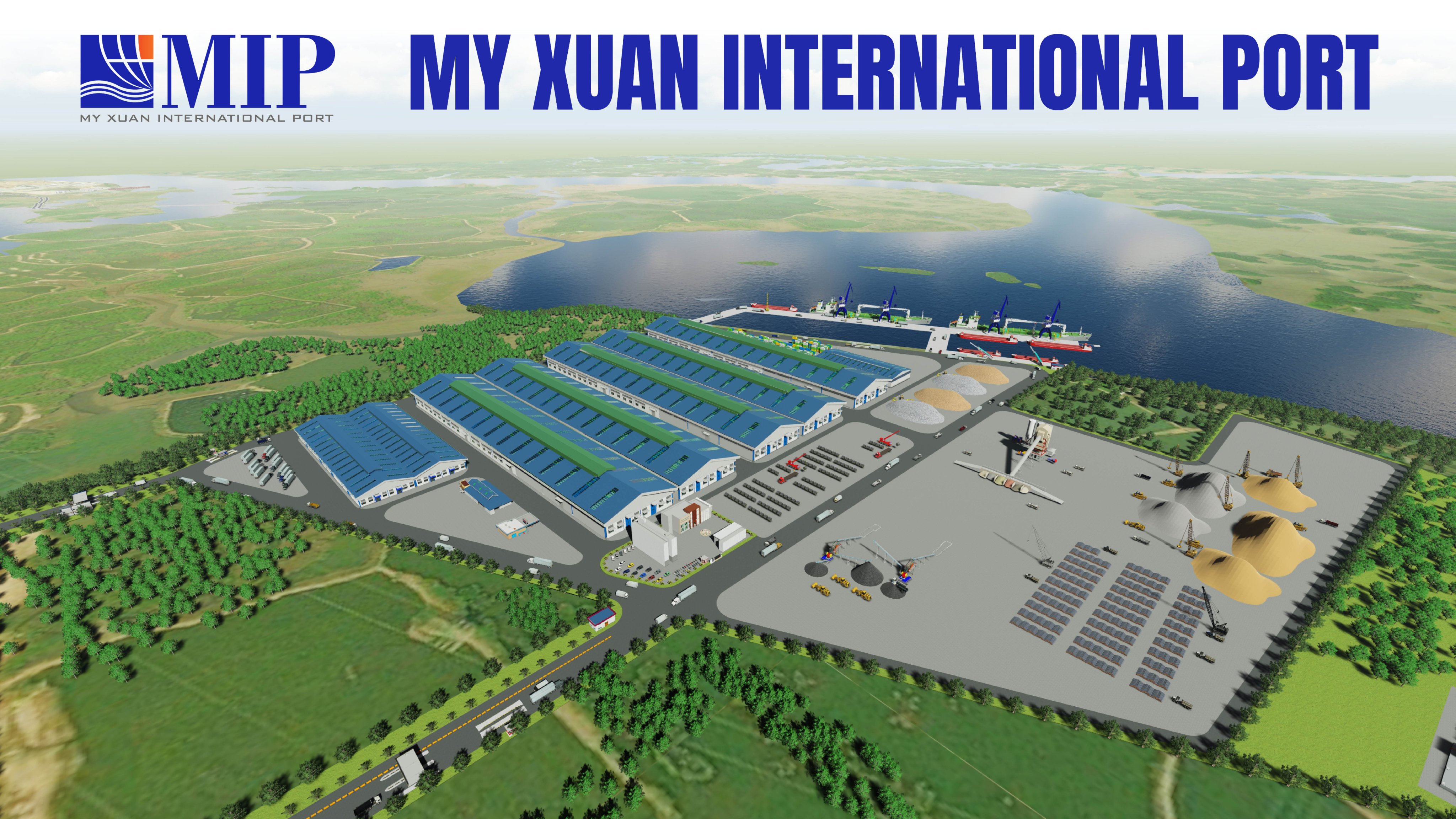

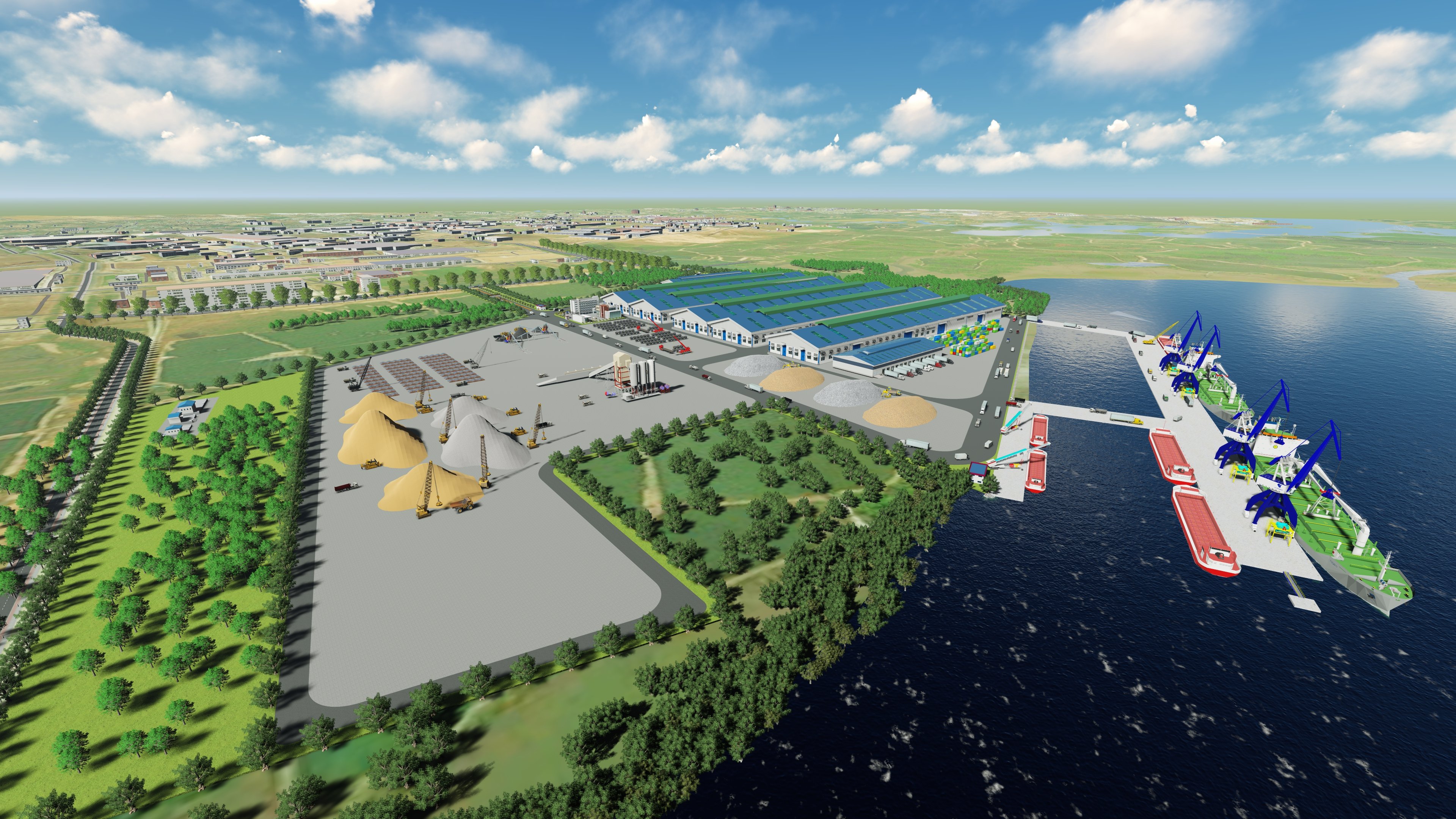

(MIP warehouse system)

The importance of warehouses in logistics

The factor that businesses are most interested in is economic efficiency, good warehouse management helps businesses save costs of production, transportation and distribution of goods, thereby creating advantages for products and services. business for customers. If the warehouse is near the port or has a convenient location in the supply and demand chain, it will create a lot of advantages for businesses. Warehousing also helps businesses maintain a stable supply, ready to deliver goods whenever customers have demand. In addition, it also provides customers with better service due to the right goods in terms of quantity, quality and condition. In general, if having a convenient warehouse location and good warehouse management, it will help businesses make a difference and increase their competitive position.

Types of warehouses in logistics

In the logistics system, there are many different types of warehouses to suit the conditions and needs of use, let's take a look at some types of warehouses below:

1. Bonded Warehouse

Among the types of logistics warehouses, bonded warehouses are one of the extremely important warehouses in the Logistics chain. This is an area of warehouses and yards established in the territory of Vietnam, separated from the surrounding area to temporarily store, preserve or perform some services for goods from abroad, or from within the country. into the warehouse according to the bonded warehouse lease contract signed between the bonded warehouse owner and the goods owner. The bonded warehouse will perform the function of temporary storage of goods, temporary preservation of shipments from abroad or at home. For goods stored here, the goods owner has the right to directly authorize the agent to carry out customs procedures, pack and reinforce the goods. And yet, here, goods owners can also transfer ownership of goods to other parties, transfer goods between bonded warehouses or border gates.

2. CFS (Container Freight Station)

CFS warehouse (also known as retail collection location), is a type of specialized warehouse to collect or separate retail goods transported in the same container. CFS warehouses are often used when shippers do not have enough stock to fill a container (FCL). Services at CFS warehouses include packing, repacking, arranging and rearranging goods awaiting export. Here, the goods will be brought to the collection site to wait for import-export procedures if necessary, then split or combine containers for export abroad.

3. Tax suspension warehouse

Tax-suspension warehouse is a warehouse used to store imported raw materials and supplies that have been granted customs clearance but have not yet paid tax. Accordingly, tax-suspension warehouses are usually owned by enterprises and these enterprises will be directly responsible for and coordinate with customs authorities to inspect and supervise tax-suspension warehouses.

4. Cross Docking

This is a special type of warehouse that does not have a storage function, but only performs the function of receiving and distributing goods immediately. The time goods are kept at the Cross Docking warehouse is usually only about a day or even an hour. The condition to perform Cross Docking is that the market volatility is low and the quantity of goods is large enough. The advantage of this model is to increase the speed of goods to consumers, and at the same time reduce the cost of storing goods.

The types of warehouses in logistics all play an important role depending on the type of item and the condition of the goods. Warehouses are often quite an expensive element in the logistics chain, so if you choose a warehouse in a strategic location, adjacent to the port, effectively managing the warehouse, it will be the decisive item in terms of price. and customer service, thereby creating an outstanding advantage for the business.

Location Contact

MY XUAN INTERNATIONAL PORT LTD

My Xuan Ward, Phu My Town, Ba Ria Vung Tau Province.

Hotline: 090.1388.136, 090.9800.136.

Phone: 0254. 3897 789

Email: myxuanport@lecvietnam.com

My Xuan International Port is located in My Xuan Ward, Phu My Town, Ba Ria - Vung Tau Province (formerly My Xuan Commune, Tan Thanh District, Ba Ria Vung Tau Province). With a water surface area up to 109,000 m2, adjacent to Thi Vai River in the West. The East is contiguous to Road 7B of My Xuan A Industrial Park. The South borders on Road 2B of My Xuan A Industrial Park.

With the above prime location, My Xuan International Port is the first choice for the convenience of both waterways and roads, enhancing connectivity with neighboring areas.